A tool belt is one of the most important accessories for anyone working in construction, carpentry, electrical work, or home improvement. The right tool belt helps you stay organized, move efficiently, and reduce physical strain during long workdays. Whether you are a professional tradesperson or a DIY enthusiast, choosing the correct tool belt can significantly impact comfort, productivity, and safety.

This detailed tool belt comparison explains the different types, materials, and features available today. By understanding what makes a quality tool belt, you can confidently select one that matches your work style and long-term needs.

What Is a Tool Belt?

A tool belt is a wearable storage system designed to hold hand tools, fasteners, and accessories around the waist or shoulders. It allows workers to keep essential tools within reach while keeping both hands free. A properly designed tool belt improves workflow efficiency and minimizes unnecessary movement on the job site.

Why a Quality Tool Belt Is Essential

Using a poorly designed tool belt can lead to fatigue, discomfort, and even long-term injury. An effective tool belt distributes weight evenly and keeps tools balanced on both sides of the body. According to occupational safety research, ergonomic tool storage systems can significantly reduce strain on the lower back and hips during repetitive tasks.

A high-quality tool belt also saves time by reducing trips to toolboxes and workbenches. Over the course of a day, this efficiency adds up to measurable productivity gains.

Types of Tool Belts Explained

Standard Tool Belt

A standard tool belt is typically worn around the waist and includes several built-in pouches. This type of tool belt works well for light-duty tasks and short projects. It is commonly used by homeowners and beginners who do not carry a large number of tools.

Tool Belt with Suspenders

A tool belt with suspenders is designed to distribute weight across the shoulders rather than placing all the pressure on the waist. This style is preferred by professionals who carry heavy tools throughout the day. By reducing lower-back strain, a suspended tool belt improves comfort during extended work hours.

Modular Tool Belt Systems

Modular tool belts allow users to customize pouch placement and storage capacity. These systems are ideal for professionals who perform different tasks daily. A modular tool belt can be adjusted as job requirements change, making it a flexible and long-lasting investment.

Apron-Style Tool Belts

Apron-style tool belts are worn in front of the body and are commonly used in workshops or finishing environments. While they offer easy access to tools, they are less suitable for climbing or active movement.

Tool Belt Materials and Durability

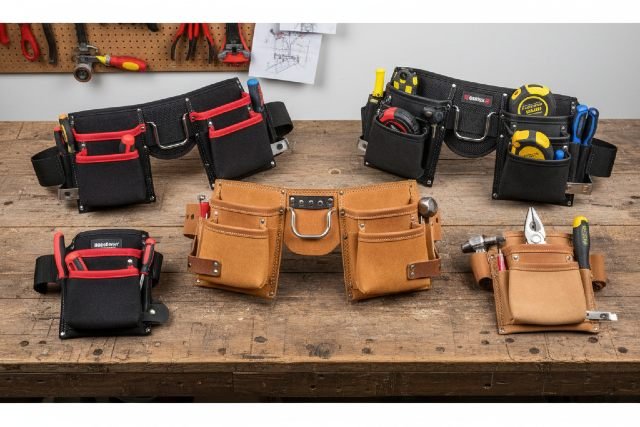

Leather Tool Belts

Leather tool belts are known for their durability and long lifespan. Over time, leather molds to the body, creating a personalized fit. This type of tool belt is popular among carpenters and framers who value strength and reliability. Although leather tool belts are heavier and more expensive, they often last for many years with proper care.

Nylon Tool Belts

Nylon tool belts are lightweight and water-resistant, making them ideal for electricians and technicians. They are easier to clean and more affordable than leather options. However, nylon tool belts may wear out faster when exposed to heavy loads or sharp tools.

Hybrid Tool Belts

Hybrid tool belts combine leather reinforcement with synthetic materials. This design balances comfort, durability, and cost, making it a practical choice for many professionals.

How to Choose the Best Tool Belt for Your Needs

Choosing the right tool belt starts with understanding your trade and daily workload. Professionals who carry heavy tools benefit from suspenders and reinforced materials, while light-duty users may prefer a simpler design. Fit and adjustability are also critical factors, as an improperly fitted tool belt can cause discomfort and circulation issues.

Weight distribution should be a top priority. A well-balanced tool belt reduces pressure points and helps prevent muscle strain. Padding and breathable materials further enhance comfort during long workdays.

Ergonomics and Safety Considerations

Ergonomic design plays a crucial role in tool belt performance. Studies from workplace safety organizations indicate that evenly distributed loads can significantly reduce musculoskeletal strain. A properly designed tool belt supports natural movement and minimizes fatigue, allowing workers to maintain focus and efficiency.

Safety is also improved when tools are securely stored. A stable tool belt reduces the risk of dropped tools, which can lead to injuries on job sites.

Real-World Tool Belt Performance

Many professionals report noticeable improvements after upgrading to a better tool belt. Contractors who switch from basic models to ergonomic or modular systems often experience less back pain and faster task completion. These real-world results highlight the importance of choosing a tool belt that matches both physical needs and job demands.

Tool Belt Maintenance and Longevity

Maintaining your tool belt extends its lifespan and ensures consistent performance. Leather tool belts should be cleaned and conditioned regularly to prevent cracking. Nylon tool belts benefit from routine washing to remove dirt and debris. Storing your tool belt in a dry environment also helps prevent material degradation.

Conclusion

A tool belt is more than a simple accessory; it is a vital piece of work equipment that directly affects comfort, safety, and productivity. By comparing tool belt styles, materials, and ergonomic features, you can select the best option for your specific needs.

Investing in the right tool belt leads to better organization, reduced fatigue, and improved performance on every job. Whether you are a professional tradesperson or a dedicated DIY user, the right tool belt will support your work for years to come.